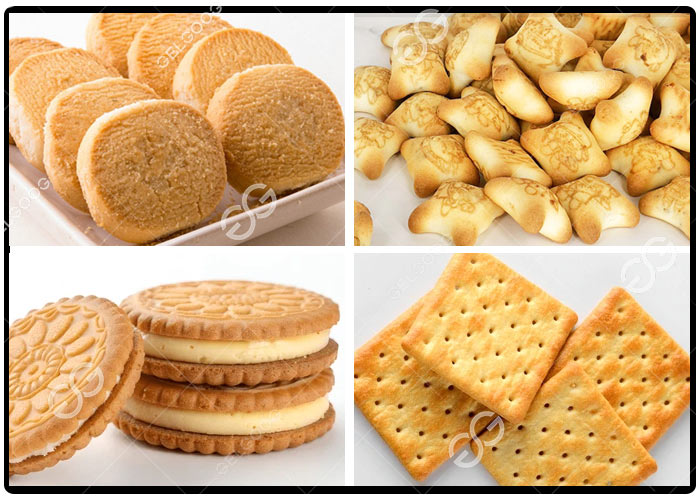

Products

The automation biscuit production system is based on PLC control. Through centralized control and intelligent sensing, it achieves precise coordination between various processes. This system is suitable for continuous production of various biscuit types.

The biscuit system consists of multiple equipment, including a mixer, forming machine, tunnel oven, cooling conveyor line, and packaging system. The entire line can be flexibly customized according to the customer's factory layout and product type.

What Are the Components of Automation Biscuit Production System?

♦︎ Raw Material Dosing and Mixing System: The automatic dosing system precisely delivers flour, sugar, oil, and other ingredients according to the recipe, while the high-speed mixer guarantees thorough and uniform dough blending.

♦︎ Biscuit Forming System: Depending on the product type, it can be configured with roller printing, roller cutting, or other forming methods. The size and thickness of the formed biscuits are uniform.

♦︎ Biscuit Baking System: The tunnel oven uses electric or gas heating and has temperature zone control. Intelligent temperature control can adjust the temperature of each section to ensure consistent biscuit color and crisp texture.

♦︎ Biscuit Cooling and Conveying System: After baking, the biscuits enter the cooling system via an automatic conveyor belt. Ensure the biscuits are thoroughly cooled to prevent deformation and sticking.

♦︎ Automatic Packaging System: After cooling, the biscuits directly enter the automated feeding and packaging process. Individual packaging, family packs, and other formats can be configured according to customer needs.

Video of Production Line for Making Biscuits

Applications of Complete Biscuit Production System

This automated biscuit system is widely used in large biscuit factories, integrated baking enterprises, and food groups. It is particularly suitable for customers with continuous, high-standard production needs, such as export-oriented enterprises or OEM manufacturers.

Through full-line automated control, not only can biscuit quality be stabilized, but companies can also achieve lean production management and enhance market competitiveness. This biscuit processing system is suitable for continuous production of various biscuit types, including hard biscuits, soft biscuits, and sandwich biscuits.

Advantages of Automatic Biscuit Production Line System

◼︎ Flexible production, seamless switching: One automated biscuit system is compatible with the production of 10+ categories including shortbread, chewy biscuits, sandwich biscuits, and biscuits.

◼︎ Quick changeover: Changeover time is reduced by 70%, quickly responding to market demands and reducing repeated equipment investment costs.

◼︎ Dedicated process support team:

- Provides recipe debugging and parameter optimization services, solving the pain point of "buying equipment but not being able to produce the product."

- The factory regularly updates its global database of popular biscuit processing techniques.

- Remote fault diagnosis + 48-hour online engineer service ensures zero downtime in your production.

◼︎ Modular design: Freely combine molding, filling, spraying, and baking modules according to product requirements. One production line equals many production lines, capable of handling both small-batch customization and large-scale mass production.

◼︎ Transparent intelligent manufacturing experience: Our 5000㎡ biscuit demonstration factory is open for tours all day, allowing you to witness firsthand the same equipment producing 200,000 packs per day.

◼︎ Support for trial production with supplied materials: We provide a 1-hour production line test, allowing you to verify the automatic biscuit production system's compatibility with your raw materials.

|

Model |

Capacity |

Inner Width of Tunnel Oven |

Heating Method |

Dimensions |

Voltage |

|

GG-BG400/420 |

100-250kg/h |

400/420mm |

Electric,Gas |

L45m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG600 |

250-400kg/h |

600mm |

Electric,Gas |

L50m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG800 |

500-800kg/h |

800mm |

Electric,Gas,Diesel |

L100m*W5m*H2.5m |

380V 50HZ 3PH |

|

GG-BG1000 |

800-1000kg/h |

1000mm |

Electric,Gas,Diesel |

L105m*W12m*H3m |

380V 50HZ 3PH |

|

GG-BG1200 |

800-1200kg/h |

1200mm |

Electric,Gas,Diesel |

L120m*W15m*H3m |

380V 50HZ 3PH |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language