Products

Product Introduction

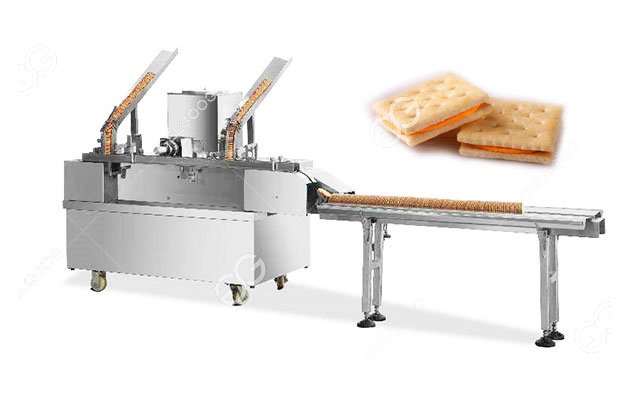

The bear biscuit production line is a high quality production line, industrial machinery designed to efficiently produce chocolate filled bear shaped biscuits at a capacity of 500 kilograms per hour.

This production line incorporates various stages of biscuit dough mixing, filling, forming, baking, oil spraying and packaging to streamline the manufacturing process and ensure consistent high-quality output.

Key Equipment and Features:

●Biscuit Dough Mixing Machine: The chocolate filled bear biscuit production line begins with a dough mixing machine. It accurately blends the required ingredients to create the biscuit dough with the perfect texture and taste.

●Bear Biscuit Forming Machine: The dough is then fed into the forming and cutting section, where bear-shaped biscuit molds are used to shape the dough into adorable bear designs. The cutting process ensures uniformity in size and shape for each biscuit.

●Baking Oven: The shaped biscuit dough is conveyed through a baking oven, where it undergoes a carefully controlled baking process to achieve the desired color, texture, and taste. The oven's advanced temperature and humidity control ensure consistent results.

●Chocolate Filling System: Once the bear biscuits are baked and cooled, the production line incorporates an automated chocolate filling system. This system precisely deposits a delicious chocolate filling into the center of each bear-shaped biscuit. The filling quantity can be adjusted as per the desired product specifications.

●Cooling and Solidification Line: The chocolate filled biscuits are then cooled to allow the filling to solidify properly. This step ensures that the chocolate remains in its ideal form, creating a delightful taste and texture experience.

●Packaging Machine: The bear biscuit line also includes a packaging and wrapping unit, which automatically packs the chocolate-filled bear biscuits into various packaging options, such as pouches, flow packs, or boxes. The packaging process maintains product freshness and extends shelf life.

Video of Automatic Bear Biscuit Production Line

The company can not only provide a professional chocolate bear biscuit line with a production capacity of 500 kg/hour, but also we can provide the ranging from 300 kilograms to 1250 kilograms.

Its innovative design and reliable performance make it an ideal solution for producing delicious chocolate-filled bear biscuits that can captivate consumers' taste buds in the market. This line is an excellent choice for large-scale biscuit manufacturing operations, providing efficient production, consistent product quality, and automation for increased productivity.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Get A Free Quote

Related Machines

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language