Products

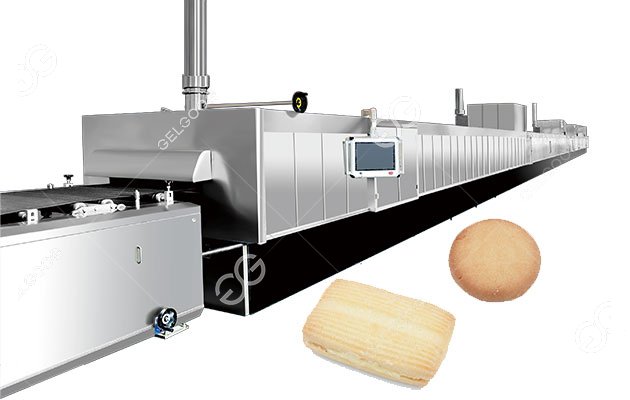

This biscuit making equipment is an automated biscuit manufacturing system designed for large-scale food factories. It is suitable for high-volume, continuous biscuit production, improving production efficiency and maintaining consistent quality.

The entire production line, from dough mixing, shaping, baking to oil spraying, cooling, finishing, and packaging, is automated. It meets diverse user needs, offering various production capacities from 200 kg to 2000 kg.

Features of the Biscuit Making Equipment

- High capacity and continuous, stable biscuit production. This machine is suitable for large scale, high volume automated food factories.

- Modular structure for easy installation and disassembly. Different biscuit styles can be produced by changing the forming machine or switching to different equipment.

- The entire biscuit processing equipment is equipped with a PLC touch-screen interface with adjustable parameters. Biscuit processing can be stored, reducing operational complexity.

- The tunnel oven uses electric or gas heating, with independent temperature zone control, ensuring uniform baking and low energy consumption.

- Parts in contact with food are made of 304 stainless steel. Clean and hygienic, with smooth, seamless welded surfaces, meeting HACCP requirements.

- Biscuit molds can be quickly changed. Suitable for producing biscuits of various sizes and shapes, meeting the needs of multi-product production lines.

- Low maintenance costs. Key components use well-known brands, ensuring long lifespan and extended maintenance cycles, reducing downtime.

Applications of Biscuit Manufacturing Equipment

Widely applied in the industrial-scale production of a variety of products, including hard biscuits, soft biscuits, cookies, sandwich biscuits, cereal biscuits, compressed biscuits, and more.

This large scale equipment is suitable for food processing plants, branded biscuit manufacturers, OEM/ODM factories, large baking enterprises, and companies with factories but not in the food industry.

Essential Equipment for Biscuit Processing

- Shaping Machine: Processes dough into biscuit blanks of specified shapes and sizes.

- Tunnel Oven: Used for continuous baking of biscuits, ensuring even heating and consistent color.

- Spraying Machine: Evenly sprays edible oil onto the biscuit surface, enhancing taste and appearance.

- Cooling Line: Rapidly cools baked biscuits for easier stacking and packaging.

- Biscuit Sorting Machine: Automatically sorts, aligns, and arranges biscuits, ensuring smooth and efficient packaging.

- Packaging Machine: Used to package biscuits, improving packaging efficiency and ensuring consistent biscuit appearance.

Frequently Asked Questions about Biscuit Making Equipment

Q1. Can it produce multiple types of biscuits?

A: Yes. By changing the molds or forming methods (such as roller cutting, roller printing, wire cutting), it can produce cookies of various sizes and shapes.

Q2. Can it be customized according to the existing factory layout?

A: Customization of this automatic biscuit equipment is supported, including capacity, machine length, heating method, factory layout diagram, etc.

Q3. Is it easy to maintain? Does it require a large number of workers?

A: The equipment is highly automated, allowing 2–3 operators to run the entire production line. Cleaning is quick, and maintenance costs are minimal.

|

Model |

Capacity |

Inner Width of Tunnel Oven |

Heating Method |

Dimensions |

Voltage |

|

GG-BG400/420 |

100-250kg/h |

400/420mm |

Electric,Gas |

L45m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG600 |

250-400kg/h |

600mm |

Electric,Gas |

L50m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG800 |

500-800kg/h |

800mm |

Electric,Gas,Diesel |

L100m*W5m*H2.5m |

380V 50HZ 3PH |

|

GG-BG1000 |

800-1000kg/h |

1000mm |

Electric,Gas,Diesel |

L105m*W12m*H3m |

380V 50HZ 3PH |

|

GG-BG1200 |

800-1200kg/h |

1200mm |

Electric,Gas,Diesel |

L120m*W15m*H3m |

380V 50HZ 3PH |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language