Products

To meet the growing demand for high-quality biscuits in Europe and South America, many manufacturers are investing in a biscuit production line turnkey solution. This solution provides a complete, automated, and reliable system for biscuit manufacturing.

In recent years, the global biscuit industry has seen continuous growth. To meet this demand, GELGOOG offers a one-stop solution covering the full process from design to installation. This helps factories start production faster and more efficiently.

What Is A Biscuit Production Line Turnkey Solution?

A turnkey solution means the manufacturer takes full responsibility for the entire production line project. From factory layout design, equipment manufacturing, line integration, electrical control, installation, training, and after-sales support, GELGOOG delivers a ready-to-run biscuit factory system.

Our biscuit turnkey solutions are suitable for different biscuit types, such as hard biscuits, soft biscuits, sandwich biscuits, cookies, crackers, lady fingers, and compressed biscuits. They can be flexibly configured to meet your production needs.

Main Equipment in the GELGOOG Biscuit Production Line

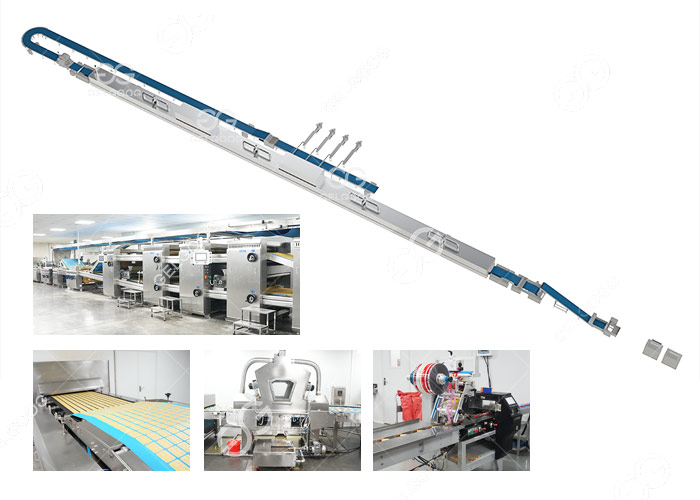

- Dough Mixing System: The dough mixer evenly mixes the ingredients, cuts the dough, and then conveys it to the forming section.

- Forming Section: The dough is formed using sheeter and forming machines. The molds can be quickly changed to produce different biscuits.

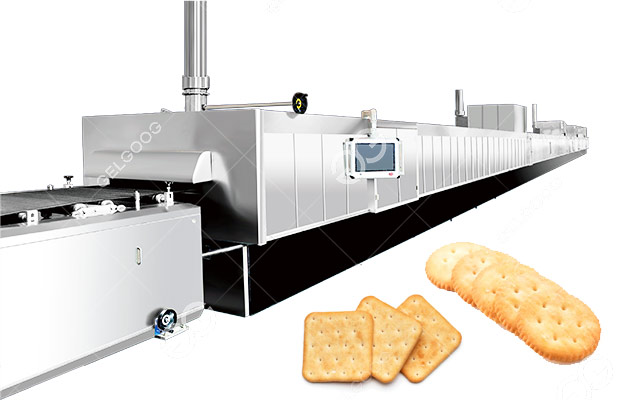

- Baking System: Tunnel oven equipped with precise temperature zones, allows for uniform baking of various biscuits.

- Cooling and Conveying System: The biscuits are conveyed via a cooling conveyor line over a length of more than ten meters to maintain their texture.

- Packaging Section: Automated stacking and counting functions are included. The biscuits are sealed and packaged in elegant bags/boxes.

- Control and Monitoring System: The entire biscuit production line solution is managed and monitored using a PLC and HMI.

All of these components were meticulously designed and integrated by GELGOOG engineers, creating an automated biscuit turnkey solution that operates stably and can handle different biscuit types.

Why Choose A Biscuit Production Line Turnkey Solution from GELGOOG

- One-Stop Solution: All systems are designed, manufactured, and installed by GELGOOG, eliminating the hassle of coordinating with multiple suppliers.

- Multi-Product Compatibility: One production line can produce different biscuit types with simple adjustments. This makes it suitable for developing biscuit plants with diverse flavors.

- Customized Design: Every biscuit line has unique space, energy, and product requirements. GELGOOG offers customized layouts, capacity options, and technical designs tailored to each customer's needs.

- Fast Installation and Commissioning: Biscuit turnkey solution expedite project completion, from equipment delivery to initial production, reducing downtime and investment risk.

- Comprehensive After-Sales Support: GELGOOG provides on-site installation, operator training, and lifetime technical support. Our engineers offer remote and local assistance to ensure smooth operation.

- Energy Efficiency and Cost Control: All systems are optimized for energy savings and long-term reliability, helping customers reduce operating costs and achieve sustainable production.

Years of Installation Experience

GELGOOG's biscuit production line turnkey solution is ideal for both new factory setups and capacity expansion projects. It has been successfully installed in Jamaica, Sudan, Saudi Arabia, Nigeria, Uzbekistan, Brazil, and Russia, helping clients produce a wide range of biscuits for retail and export markets.

Whether you're planning a small or medium sized factory or a high volume industrial biscuit line, GELGOOG's turnkey system can meet your production needs. Produce high quality biscuits, improve your product quality, and build a popular brand.

|

Model |

Capacity |

Inner Width of Tunnel Oven |

Heating Method |

Dimensions |

Voltage |

|

GG-BG400/420 |

100-250kg/h |

400/420mm |

Electric,Gas |

L45m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG600 |

250-400kg/h |

600mm |

Electric,Gas |

L50m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG800 |

500-800kg/h |

800mm |

Electric,Gas,Diesel |

L100m*W5m*H2.5m |

380V 50HZ 3PH |

|

GG-BG1000 |

800-1000kg/h |

1000mm |

Electric,Gas,Diesel |

L105m*W12m*H3m |

380V 50HZ 3PH |

|

GG-BG1200 |

800-1200kg/h |

1200mm |

Electric,Gas,Diesel |

L120m*W15m*H3m |

380V 50HZ 3PH |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language