Products

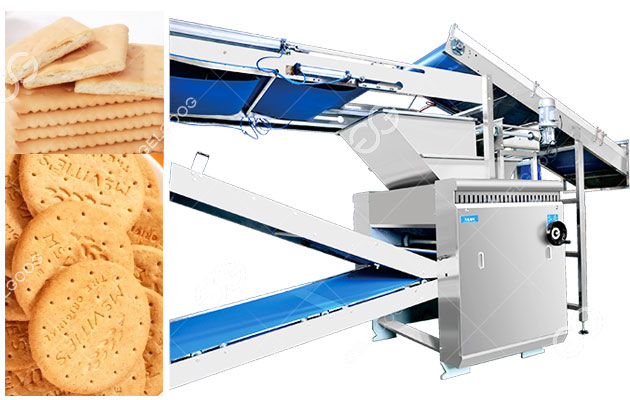

Our company has developed a digestive biscuit production line capable of continuous production. This line utilizes an intelligent system combined with sophisticated baking technology, resulting in an efficient production process and high-quality finished products.

It's ideal for large-scale food manufacturers looking to increase productivity while maintaining product quality. Best of all, this digestive biscuit line can be customized to suit different production capacities and biscuit varieties.

Features of Digestive Biscuit Production Line

- High Automation: Reduces manual labor with automated mixing, forming, baking, and packaging processes.

- Customizable Output: Adjustable settings for thickness, shape, and size to meet diverse market demands.

- Energy-Efficient Baking: Advanced oven technology ensures even baking while reducing energy consumption.

- Hygienic Design: The digestive biscuit processing line is made from food-grade stainless steel, complying with international food safety standards.

- Easy Maintenance: User-friendly controls and accessible components for quick cleaning and servicing.

- Intelligent Temperature Control System: Multi-zone baking with real-time temperature adjustment ensures even coloring and precise moisture control (3-5%).

- Quick-change Tooling Design: Modular components of digestive biscuit line enable product changeover in under 15 minutes with <2% material waste during transitions.

What Are Digestive Biscuits?

Digestive biscuits are semi-sweet, whole wheat-based cookies known for their crisp texture and mild flavor. Originally developed for their digestive benefits (due to baking soda content), they are now popular as a snack or tea-time biscuit. They can be plain or coated with chocolate, making them versatile for different consumer preferences.

Digestive Biscuit Production Process

This automatic digestive biscuits line includes: Prepare Recipe → Dough Mixing → Cutting & Sheeting → Digestive Biscuit Forming → Digestive Biscuit Baking → Biscuit Spraying → Cooling → Digestive Biscuit Packing

- Mixing: Combine flour, sugar, butter, baking soda, and other ingredients into a uniform dough.

- Cutting & Sheeting: Cut the dough into cube and then press it into thin sheets.

- Digestive Biscuit Forming: The sheets are pressed by a roll forming machine and printed with a uniform pattern. Scrap collection and reuse.

- Digestive Biscuit Baking: Bake at controlled temperatures to give digestive biscuits a nice appearance and crispy texture.

- Cooling: Use a cooling conveyor belts, allow digestive biscuits to cool to room temperature for optimal texture.

- Packaging: Use airtight containers or wrapping tape to package digestive biscuits to maintain freshness.

Video of Automatic Digestive Biscuit Production Line

Essential Equipment in A Digestive Biscuit Processing Line

- Dough Mixer—Used for uniform dough preparation.

- Biscuit Forming Machine—Forms the dough into digestive biscuits.

- Digestive Biscuit Tunnel Oven—Adjusts temperature and time to ensure even baking.

- Oil Sprayer—Enhances the color and texture of the biscuits.

- Cooling Conveyor—Cools the biscuits before packaging to prevent deformation.

- Packaging Machine—Seals the digestive biscuits in bags, boxes, or wrappers.

Why Our Digestive Biscuit Production Line is in High Demand?

Our digestive biscuit production line for sale is a top choice for manufacturers due to its reliability, efficiency, and adaptability. With growing demand for digestive biscuits globally, investing in this automated line ensures high production capacity with minimal waste. Clients appreciate the customizable options, energy-saving features, and compliance with food safety regulations.

For businesses looking to expand their digestive biscuit production, this line offers a cost-effective and high-performance solution. Contact us today to get the best digestive biscuit production line tailored to your needs! Email: lisa@gelgoog.com, whatsapp/wechat: +8615515571373.

|

Model |

Capacity |

Inner Width of Tunnel Oven |

Heating Method |

Dimensions |

Voltage |

|

GG-BG400/420 |

100-250kg/h |

400/420mm |

Electric,Gas |

L45m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG600 |

250-400kg/h |

600mm |

Electric,Gas |

L50m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG800 |

500-800kg/h |

800mm |

Electric,Gas,Diesel |

L100m*W5m*H2.5m |

380V 50HZ 3PH |

|

GG-BG1000 |

800-1000kg/h |

1000mm |

Electric,Gas,Diesel |

L105m*W12m*H3m |

380V 50HZ 3PH |

|

GG-BG1200 |

800-1200kg/h |

1200mm |

Electric,Gas,Diesel |

L120m*W15m*H3m |

380V 50HZ 3PH |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language