Products

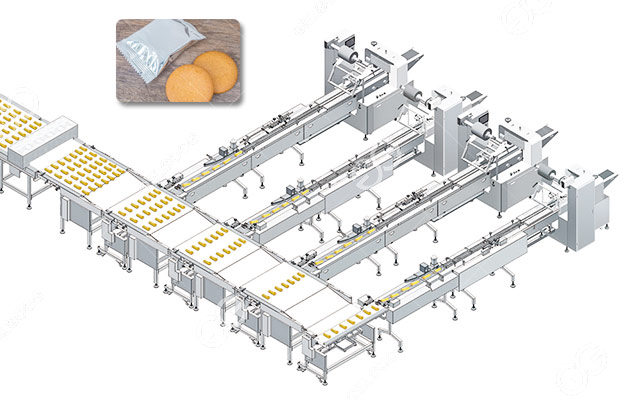

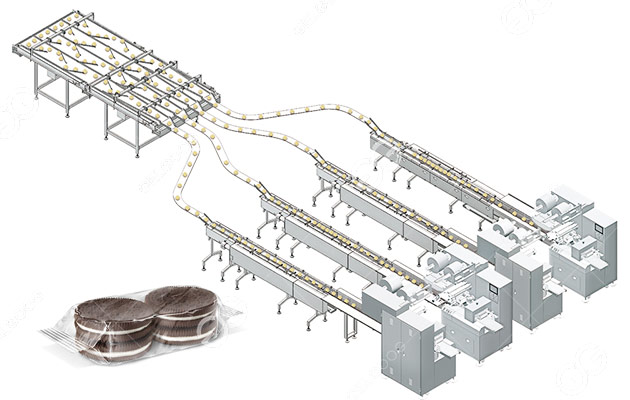

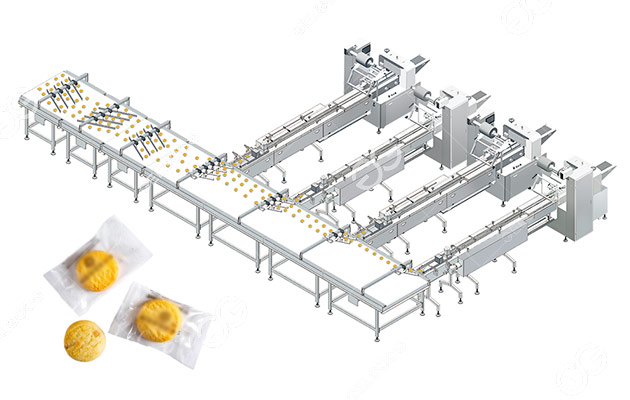

Automatic biscuit packaging line is mainly used for sorting, counting, conveying, and automatically packaging biscuits. They enable continuous, high-speed packaging processes, increasing production capacity.

The core advantages of this packaging line lie in its stable performance, high-speed operation, and adaptability to biscuits of different shapes and sizes. It is suitable for baking companies to upgrade their production efficiency and reduce labor costs.

Main components of Automatic Biscuit Packaging Line

- Automatic sorting machine: Corrects the orientation of scattered biscuits and automatically arranges them, improving packaging consistency.

- Dividing and Distributing Device: Evenly distributes biscuits into multiple packaging channels, enabling high-speed, one-to-many packaging.

- Intelligent Counting System: Automatically counts biscuits according to demand, such as quantitative combinations of 3, 5, or 10 biscuits.

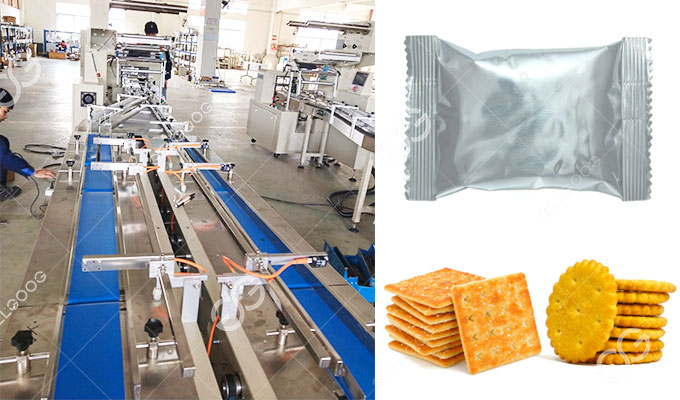

- Synchronous Conveyor Line: Maintains stable and equidistant conveying of biscuits, reducing collisions and breakage.

- Pillow-Type Automatic Packaging Machine (Flow Pack): Completes automatic bagging, filling, cutting, and sealing processes, enabling high-speed continuous packaging.

- Central Control System (PLC + Touch Screen): Used for overall line data adjustment, speed synchronization, fault diagnosis, and status monitoring.

Features of Automatic Biscuit Packaging Machine

- High automation: Fully automatic operation from sorting to packaging, greatly reducing manual intervention.

- High speed and stability: Multi-channel feeding structure can meet the needs of large-scale production.

- High compatibility: The biscuit packaging line can adapt to biscuits of different shapes, sizes, and thicknesses, eliminating the need for frequent parts changes.

- Intelligent control: The PLC system enables synchronized control of the entire line, with a user-friendly interface and freely adjustable parameters.

- Reduced breakage: The entire line is designed according to food characteristics, ensuring smooth conveying and effectively reducing biscuit breakage.

- Easy cleaning and maintenance: The equipment uses a stainless steel structure, and key parts are easily disassembled for convenient daily hygiene management.

- High scalability: The machine supports integration with metal detectors, weighing machines, case packing machines, and other equipment.

Biscuit Packing Line Application Scope

This packaging line is suitable for large biscuit factories, food processing companies, e-commerce supply chain factories, and production environments with high requirements for packaging speed, capacity, and yield.

Applicable products include a variety of baked goods such as biscuits, cookies, sandwich cookies, wafers, and small cakes. Whether packaged as a single piece, multiple pieces, or a combination pack, the desired packaging can be achieved by adjusting the counting and packaging parameters.

The automatic biscuit packaging line provides food companies with a highly efficient, stable, and scalable automation solution through a highly integrated sorting, counting, and high-speed packaging system. It not only significantly improves production efficiency and reduces labor costs but also ensures product packaging consistency and hygiene safety, providing strong support for the modernization and upgrading of biscuit production lines.

|

Model |

Capacity |

Inner Width of Tunnel Oven |

Heating Method |

Dimensions |

Voltage |

|

GG-BG400/420 |

100-250kg/h |

400/420mm |

Electric,Gas |

L45m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG600 |

250-400kg/h |

600mm |

Electric,Gas |

L50m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG800 |

500-800kg/h |

800mm |

Electric,Gas,Diesel |

L100m*W5m*H2.5m |

380V 50HZ 3PH |

|

GG-BG1000 |

800-1000kg/h |

1000mm |

Electric,Gas,Diesel |

L105m*W12m*H3m |

380V 50HZ 3PH |

|

GG-BG1200 |

800-1200kg/h |

1200mm |

Electric,Gas,Diesel |

L120m*W15m*H3m |

380V 50HZ 3PH |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language