Products

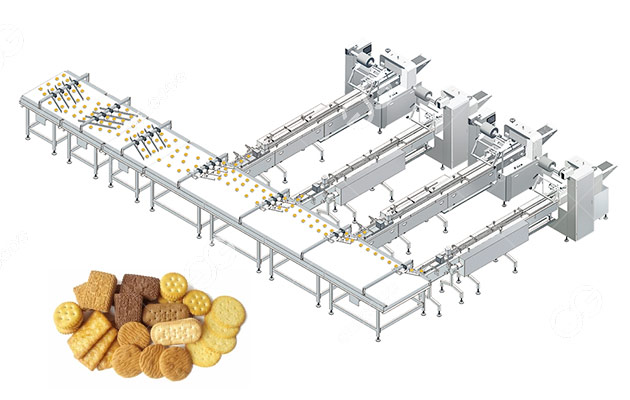

The biscuit packaging line is a crucial component of biscuit production. After baking and cooling, the biscuits need to be neatly arranged, counted, and packaged before reaching the market.

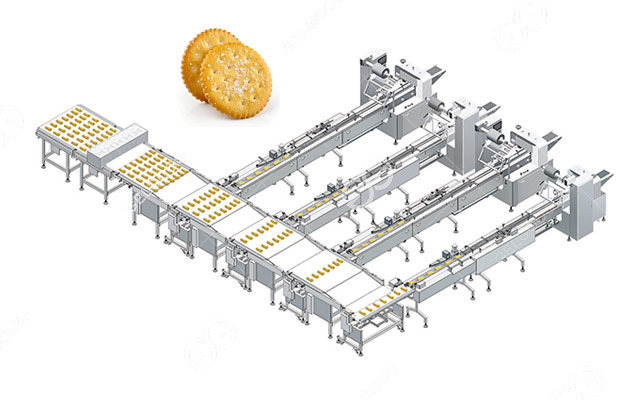

This complete packaging line integrates feeding, sorting, and packaging into a continuous process. It can package the biscuits quickly and ensures hygienic packaging. With increasing demand for high product quality and rising labor costs, more and more factories are choosing packaging systems.

Main Components and Workflow of Biscuit Packaging Line

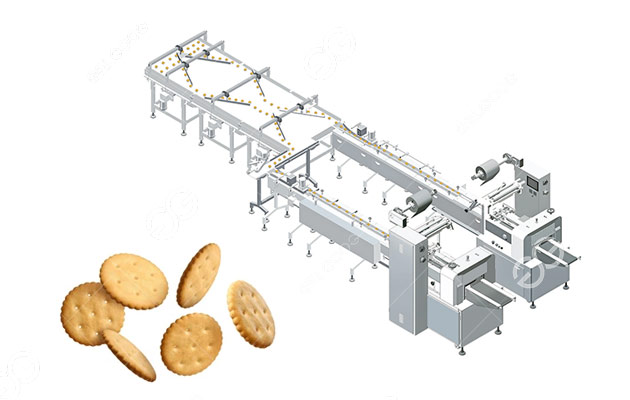

Main Components: This packaging line includes a conveyor system, a sorting and sizing system, a counting and stacking system, a packaging machine, and an automatic coding system.

Workflow: After cooling, the biscuits are transported by a conveyor belt to the automatic sorting section, where they are then transported to the packaging section. Depending on the biscuit type, single or multi-piece packaging can be selected.

The machine automatically counts, packs, seals, and codes the biscuits. This packaging process is fast and efficient, minimizing manual labor while maintaining the sanitation and integrity of the biscuits.

Packaging Line Applications

This complete biscuit packaging line is widely used in bakery factories, confectionery factories, biscuit production plants, and other food processing companies. It can be used to package soft and hard biscuits, sandwich biscuits, cookies, and more.

We offer different models and configurations of packaging line equipment to meet different production capacities and packaging styles. We can also add labeling equipment and other features to meet your needs.

Advantages of Automatic Biscuit Packaging Line

- Fast packaging speed: This machine can achieve a packaging speed of 200-400 packs per minute, depending on the biscuit type and lane configuration.

- Stable operation: Continuous feeding and synchronous control ensure biscuit packaging accuracy exceeding 98%, reducing product loss.

- Reduced labor: 2-3 workers operator can manage one or more complete biscuit packaging line, reducing labor requirements by 60-70% compared to conventional packaging machines.

- Excellent sealing effect: The temperature-controlled seal effectively blocks air and moisture, keeping cookies fresh and extending their shelf life by approximately 20–30%.

- Flexible packaging formats: Packaging line for biscuits has a variety of packaging styles are supported, including single packs, family packs, and trays—with quick switching between packaging formats.

- Hygienic design: The packaging line's stainless steel construction and easy-to-clean surfaces meet food safety standards and ensure a clean production environment.

As a professional biscuit packaging line manufacturer, GELGOOG provides complete packaging solutions, including design, installation, and after-sales service. Each line is carefully designed to deliver stable performance and a long service life, helping biscuit producers improve efficiency.

The price of a biscuit packaging line depends on its capacity, automation level, and configuration. If you want to buy the packaging line for biscuits, please contact us. We will send you the suitable quotation.

| Model | GG-ZS250X |

| Width of Film | Max.250mm |

| Length of Bag | 65~190mm or 120~280mm |

| Width of Bag | 30~110mm |

| Height of Product | Max.40mm |

| Film Roll Diameter | Max.320mm |

| Packing Speed | 40~230bags/min |

| Power | 220V,50/60HZ,2.4KVA |

| Size | (L)3920×(W)670×(H)1320 |

| Weight | 800Kg |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language