Products

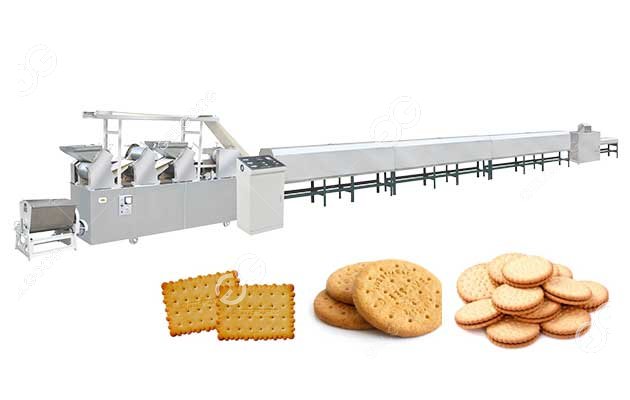

This is a professional soft biscuit forming machine, commonly known as a rotary moulder. It is primarily used to produce soft biscuit dough in various shapes. Its automated operation improves production efficiency and product quality.

It is a key equipment in a soft biscuit production line. Its precise mechanical operation replaces traditional manual rolling and mold cutting, achieving fully automated operations from dough to forming.

How the Soft Biscuit Forming Machine Operates

First, the mixed soft dough is placed into the machine's inlet hopper. The dough is then fed into a chamber. Inside the chamber are two counter-rotating rollers: one is a smooth feed roller, and the other is a mold roller with soft biscuit shapes carved into it.

The feed roller presses the dough into the grooves of the mold roller. As the mold roller rotates, a scraper scrapes away any excess dough. The formed dough pieces are then precisely dropped onto a conveyor belt below, ready for baking in the oven.

Features of Rotary Moulder Machine

- Precise Forming: Perfectly reproduces the details of soft biscuit patterns, ensuring consistent and beautiful soft biscuit appearance.

- High production efficiency: The soft biscuit forming machine operates smoothly and features adjustable speed. Suitable for continuous large-scale production.

- Wide application: Easily replace molds, allowing for the rapid production of soft biscuits with various designs.

- Low residue: The machine's smooth interior and efficient scraper system minimize dough residue, saving costs.

- High-quality materials: The soft biscuit rotary moulder machine is constructed of high-quality stainless steel and meets food hygiene and safety standards.

- Easy maintenance: The main components of equipment are easily disassembled, requiring minimal cleaning and maintenance effort.

Applications of Soft Biscuit Forming Machine

This machine has a wide range of applications. It is particularly suitable for processing low-gluten, high-fat dough with good plasticity. For example, it can produce common cookies, shortbread, Oreo, and caramel biscuits.

It covers a wide range of applications, from large food factories to medium-sized bakeries. It seamlessly integrates with upstream dough sheeter and downstream tunnel ovens to form an efficient and continuous production line.

Soft Biscuit Rotary Moulder Price

The price vary significantly depending on the model, production capacity, and configuration. Standard industrial models typically range from tens of thousands to hundreds of thousands of US dollars. The specific price depends on your production needs and technical requirements. We recommend contacting us directly for a detailed quote.

To quickly get a quote for our equipment, please contact us via the following:

- Email: lisa@gelgoog.com

- WhatsApp: +8615515571373

- Tel: 008615515571373

- WeChat: 8615515571373

This soft biscuit forming machine is crucial for achieving consistent biscuit quality. When selecting, please ensure the most appropriate model is based on the type of dough you primarily produce (soft/hard). If you have any questions, please contact us.

|

Model |

Capacity |

Inner Width of Tunnel Oven |

Heating Method |

Dimensions |

Voltage |

|

GG-BG400/420 |

100-250kg/h |

400/420mm |

Electric,Gas |

L45m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG600 |

250-400kg/h |

600mm |

Electric,Gas |

L50m*W5m*H2m |

380V 50HZ 3PH |

|

GG-BG800 |

500-800kg/h |

800mm |

Electric,Gas,Diesel |

L100m*W5m*H2.5m |

380V 50HZ 3PH |

|

GG-BG1000 |

800-1000kg/h |

1000mm |

Electric,Gas,Diesel |

L105m*W12m*H3m |

380V 50HZ 3PH |

|

GG-BG1200 |

800-1200kg/h |

1200mm |

Electric,Gas,Diesel |

L120m*W15m*H3m |

380V 50HZ 3PH |

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language