Biscuit Making Plant Project Report from GELGOOG

The biscuit making plant project aims to establish a modern production facility that can produce a wide variety of biscuits efficiently and profitably.

With the steady growth of the global snack food market, biscuits remain one of the most consumed bakery items worldwide. Setting up a biscuit manufacturing plant offers excellent business potential due to increasing demand in both domestic and export markets.

Biscuit Making Plant Project Process

- Dough Mixing: Ingredients such as flour, sugar, shortening, and flavorings are mixed using a planetary or horizontal mixer to form a uniform dough.

- Dough Feeding and Forming: The prepared dough is sheeted, cut, or molded into the desired shapes using rotary molders or cutters.

- Baking : Shaped dough pieces are baked in a tunnel or rotary oven under precise temperature control to achieve the right color and crispness.

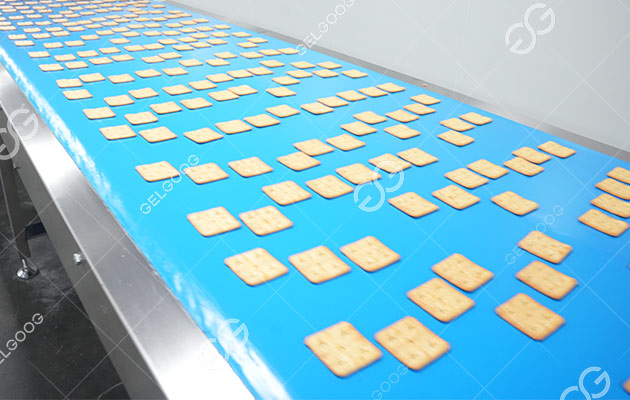

- Cooling: Freshly baked biscuits are cooled on conveyor lines to remove moisture and prevent breakage.

- Packaging : Finally, biscuits are weighed and packed automatically for distribution and sale.

Machinery Required

Setting up a biscuit plant requires several key machines that work together in one continuous line.

- Dough Mixer: Mix all ingredients uniformly to prepare biscuit dough.

- Biscuit Forming Machine: Shapes the dough through rotary molding or cutting.

- Tunnel Oven: Bakes biscuits at controlled temperatures for uniform results.

- Cooling Conveyor: The baked biscuits gradually before packing.

- Biscuit Packing Machine: Packs biscuits into pouches or cartons automatically.

Biscuit Making Plant Project Cost and Investment

For small scale production, the investment can start from USD 300,000 to 350,000. While medium scale automatic lines may cost between USD 400,000 and 500,000. Large scale production capacity is above USD 500,000.

Key cost components include:

- Machinery and installation

- Factory building and utilities (electricity, gas, water)

- Raw materials and packaging materials

- Labor and operational expenses

Advantages of Automatic Biscuit Plant Project

- Higher productivity – continuous operation with stable output.

- Consistent quality – precise control over baking time and temperature.

- Reduced labor costs – automation minimizes manual handling.

- Energy saving and easy maintenance – modern designs focus on efficiency and cleanliness.

- Flexible production – suitable for hard biscuits, soft biscuits, and sandwich types.

A biscuit making plant project is a promising business opportunity for entrepreneurs looking to enter the bakery or snack food industry. By investing in advanced biscuit machinery and adopting efficient production management, you can achieve consistent product quality, high output, and long-term profitability.

Whether you're planning a small, medium, or large-scale biscuit plant project, understanding the production process, required equipment, and investment details is the first step toward building a successful biscuit manufacturing business. Contact us for inquiries.

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language