How Automatic Biscuit Machine Reduce Labor and Waste

In the highly competitive baking industry, biscuit companies face increasing pressure. These include rising labor costs, unstable production volumes, significant raw material waste, and stricter food safety requirements.

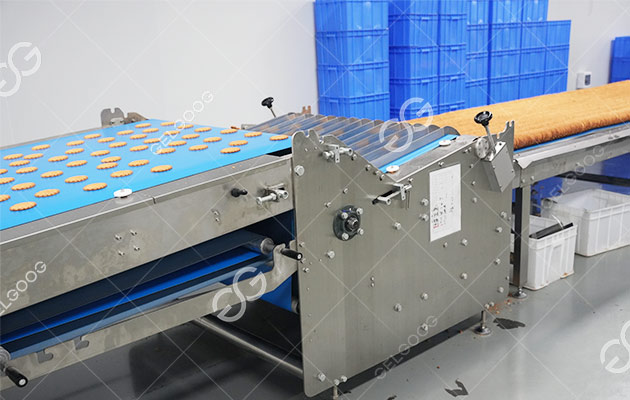

Many factories have found that continuing to rely on traditional production methods is no longer sufficient to guarantee consistent quality and competitiveness. Choosing automatic biscuit machine can effectively reduce labor and waste.

The following will explain how automated equipment can truly help businesses improve biscuit production from several perspectives. It not only replaces a significant amount of manpower but also substantially reduces waste and makes the production process more stable.

Reducing Reliance On Manual Labor Leads To More Stable Biscuit Production

Traditional biscuit production requires human labor at almost every stage: dough mixing, conveying, pressing, shaping, baking, cooling, and packaging. More workers mean more errors, and differences in operating habits between shifts can lead to inconsistent product quality.

Automated equipment can delegate these repetitive, experience-dependent tasks to machines:

- Automatic continuous dough conveying

- Automatic detection and adjustment of sheet thickness

- Consistent biscuit size and thickness

- Pre-setting and automatic control of oven temperature zones

- Automatic connection between biscuit cooling and packaging, eliminating the need for manual handling.

In a real factory, an automatic biscuit machine can typically reduce the number of workers by 8–20. More importantly, production is not affected by personnel changes, resulting in more stable capacity.

Consistent Biscuit Quality, Reduced Rework and Defects

Biscuits are highly sensitive to thickness, moisture content, and color. Differences between manual batches can lead to significant instability.

Automation ensures consistency in these key aspects:

- Precise ingredient dispensing and feeding prevents dough from varying in consistency;

- Controllable dough thickness eliminates reliance on experience for sheet forming;

- Servo-driven biscuit shaping ensures consistent size and weight;

- Intelligent tunnel ovens provide stable temperature and air circulation for more consistent biscuit baking.

Higher biscuit quality results in fewer defective products. Many factories have reduced their defect rate to around 1–2% after adopting automatic biscuit machines, significantly improving raw material utilization.

Clear Return on Investment and Lower Long-Term Costs

Considering labor input, raw material waste, rework costs, and energy consumption, the savings brought by automation equipment are significant. Most factories can recoup their investment within 12–24 months after upgrading their production lines.

Automation not only increases output but also directly enhances a company's competitiveness in the market, leading to more stable supply, more standardized products, and more controllable costs.

Automatic biscuit making machine are core equipment for baking factories to improve efficiency, reduce costs, and ensure quality. By reducing manual operation and production waste, automation makes it easier for companies to achieve stable production and long-term profitability.

For companies planning to expand, renovate, or build new factories, automated equipment is no longer an option, but an inevitable choice to enhance competitiveness.

Email:

lisa@gelgoog.com

Email:

lisa@gelgoog.com Phone:

0086-155-1557-1373

Phone:

0086-155-1557-1373

Language

Language